Leveraging 3D for Apparel Design and Manufacturing Pipelines

COVID-19 has highlighted the possibilities of a fully remote workforce that takes advantage of global talent markets and supply chains to build quality products and services efficiently and cost-effectively.

Digitalization is the future of manufacturing work

Manufacturing, in particular, has a decades-long history of managing distributed global teams, but the future of manufacturing work is in the digitalization of processes that are still usually manual, time-consuming, and expensive.

3D is critical to any manufacturing digitalization and design collaboration process. The next few years will mark a final shift from mailed physical samples to customizable samples that integrate with supply chains in real-time.

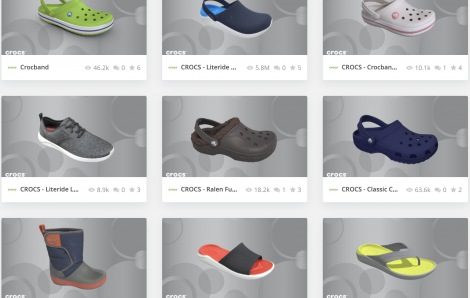

“[Digital samples] saved us from manufacturing 2500 physical samples that were once shipped to the HQ for the meetings.”

—Stefano Ferniani, Senior Director of Global Innovation at Crocs

Digitalization of the manufacturing design and delivery process is, of course, well established with mature tools. Product Lifecycle Management (PLM) and Configure Price Quote (CPQ) systems integrate CAD drawings, bills of materials, and product or project-specific data.

What these systems mostly lack, however, is high-quality 3D rendering with photorealistic materials and textures that can be easily shared and customized instantaneously with anyone on an internet connection. And this is what we’ve developed at Sketchfab.

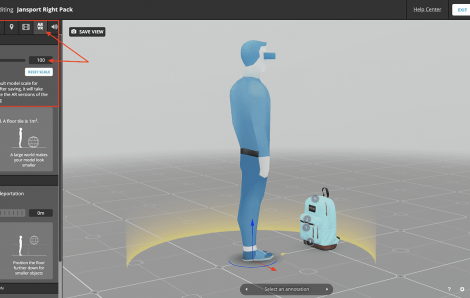

Our robust online 3D viewer lets you showcase stunning 3D models. It supports Physically Based Rendering (PBR), which allows artists and designers to display their content in the most photorealistic way possible. Designed for collaborative projects, our 3D asset management platform lets co-workers securely share, edit, and manage 3D content.

Leveraging 3D to fully digitize the supply chain

Imagine a furniture executive without design know-how sitting in her office in the US. She could instantaneously map newly sourced materials from a Beijing warehouse to a CAD design drawn by her team that morning, allowing her to see a new concept almost immediately with near-photorealistic detail.

That new visualization could be automatically saved and associated with costing and manufacturing timelines—or it could even live within the existing PLM interface!

With just one more click, high-resolution renderings could be published to an eCommerce or marketing website—or shared privately with distribution partners.

Our technology makes that workflow a reality today.

At Sketchfab, we’ve started to leverage our 3D viewer to digitize complex manufacturing workflows for major brands. We’re looking for innovators to help us connect the dots to make this (in theory simple but in practice much more complex) vision a reality for their brands.

If you’re in the process of digitizing your manufacturing activities and are in need of a 3D asset management platform, try Sketchfab! Just visit our plans page and subscribe to one of our licenses.